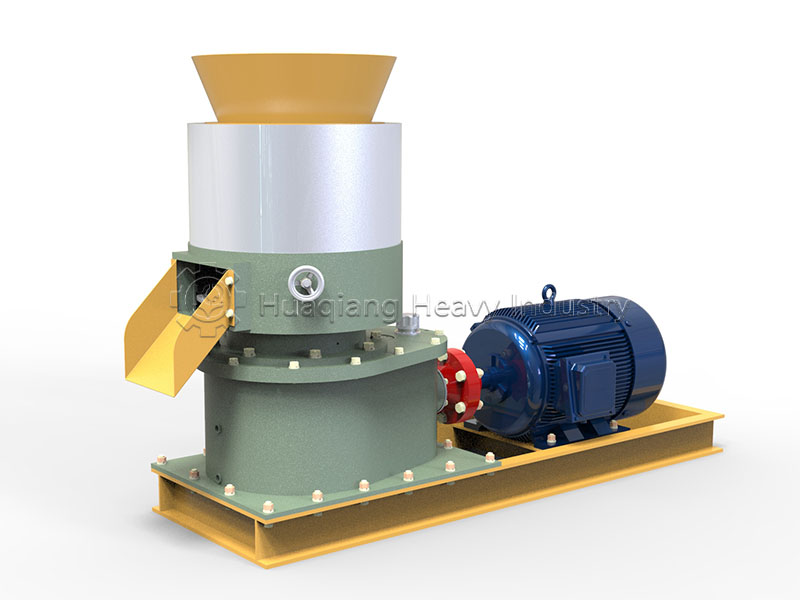

The flat die granulator is a device that granulates materials through mechanical extrusion. It uses a room-temperature granulation process and is widely used in the field of pellet forming. Its core working principle is to convey pre-treated material between a flat die and a pressure wheel. The pressure wheel, driven by power, applies pressure to the material, forcing it through the die holes in the flat die to form columnar pellets. The pellets are then cut into pellets of a set length.

This granulation method eliminates the need for high-temperature drying, maximizing the retention of active ingredients in the material and making it particularly suitable for granulating heat-sensitive materials. Compared to traditional granulation equipment, it offers a simpler and more compact structure, easier operation, and lower energy consumption. The production capacity of a single unit can be adjusted based on demand, ranging from tens of kilograms to several tons per hour, meeting the needs of production at various scales.